Ladle modification preparation

Brief introduction

There are two types of ladle modification agents: block and powder, with the main components being Al and metal oxides.

There are usually two ways to reform a ladle. 1. The slag dilution method refers to the addition of pre melted synthetic slag during the steelmaking process, which is mixed and flushed with molten steel to complete the slag transformation and steel desulfurization. 2. The slag reduction method involves adding modified agents such as CaO+Al and Al2O3+SiO2+Al after steelmaking to complete the slag transformation.

The slag dilution method is conducive to deep dephosphorization and sulfur removal, stable aluminum yield, and simple operation. The strong reducibility of aluminum in slag reduction method can reduce unstable oxides such as FeO and MnO in ladle slag, reducing the oxidation of ladle slag. Due to the reduction of unstable oxides, the oxygen content in molten steel decreases accordingly; Meanwhile, due to the deoxygenation effect of the modified preparation, the loss of acid melted aluminum in the aluminum wire and steel liquid during refining is avoided; In addition, high temperature, high alkalinity, and low oxidation atmosphere are conducive to desulfurization. The deoxidation effect of this modified agent can reduce unstable oxides such as FeO and MnO, and modify the ladle slag to form a low oxidation environment, which is very conducive to deep desulfurization and fully utilizes the desulfurization function of ladle refining.

Effect

1. Strength refers to the ability of a material to resist deformation or fracture. There are two types: yield strength σ b. Tensile strength σ S. The strength index is an important indicator for measuring structural steel, and the higher the strength, the greater the force that the steel bears;

2. Hardness refers to the ability of a material's surface to resist the pressure of hard objects. There are three common types: Brinell hardness HBS, Rockwell hardness HRC, and Vickers hardness HV. Hardness is an indicator of the surface deformation ability of steel, and the higher the hardness, the better the wear resistance of the steel; It is not easily worn out.

Advantage

1. Creating conditions for LF furnace smelting of ultra-low sulfur steel

To ensure that the sulfur content at the refining endpoint of the LF furnace is less than the original target value, it is necessary to control the original sulfur content of the slag and steel liquid, and the control of the original sulfur content of the steel liquid needs to be completed before the LF enters the station. This not only requires strict control of the sulfur content in the steel in the converter, but also requires partial desulfurization tasks to be completed during the steelmaking and transportation processes. Ladle slag modifiers can meet this requirement.

2. Implement LF refining forward shift

By modifying the ladle slag during the steelmaking process, the slag making process in the early stage of LF refining is transferred to the converter steelmaking and ladle transportation process, achieving the white slag making process in the early stage of LF.

3. Purifying molten steel

After the ladle slag modification treatment, the top slag of the ladle has a high degree of height and reducibility, which can achieve a certain degree of deoxygenation and desulfurization, and remove inclusions in the steel.

4. Shorten refining time

The use of ladle slag modifier can significantly shorten the smelting cycle of LF furnace. Due to the shortened smelting cycle, the electrification time of LF furnace is reduced, which is also beneficial for reducing electricity consumption, electrode and refractory material consumption of LF furnace.

Characteristic

1. Reduce the content of gases and inclusions in molten steel.

2. Adjusting slag and melting slag to reduce steel slag, purify molten steel, and improve its purity.

3. Deoxygenation of molten steel to prevent secondary oxidation, high deoxidation rate, and changing the concentration of molten steel.

4. Reduce the consumption of alloys and effectively improve the recovery rate of alloys.

5. Effectively adjust the performance of the slag layer and the alkalinity of the steelmaking slag, so that the inclusions in the molten steel float and form slag.

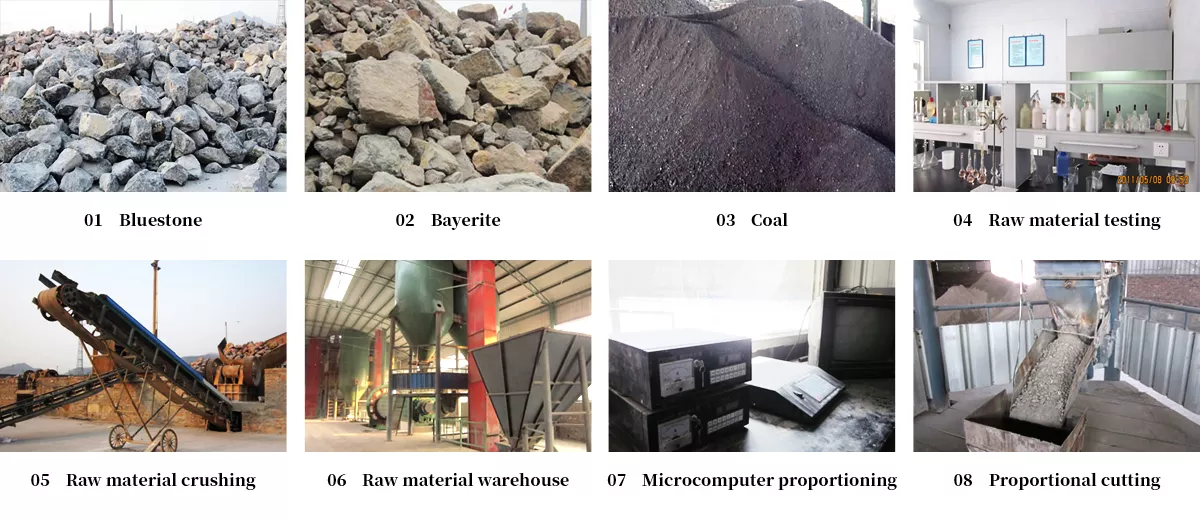

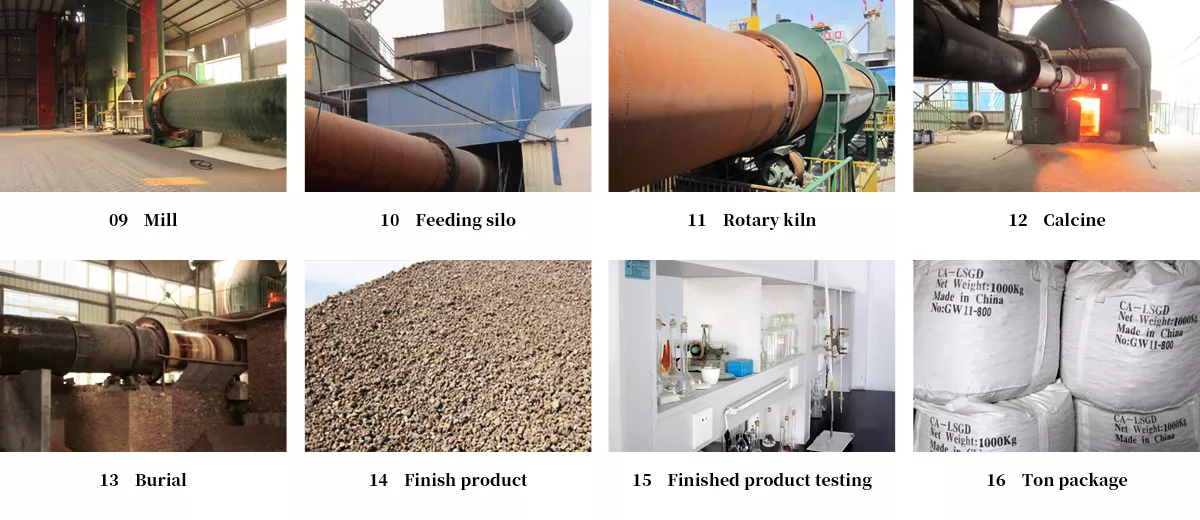

Production site

Process flow

Company profile

Gongyi Weida Co., Ltd. was founded in 1999, mainly produces refined slag, calcium aluminate, calcium aluminate powder, pre-melted refined slag, sintered refined slag and other products.The annual production capacity reaches 50,000 tons, and the products are sold well to Japan, South Korea, Vietnam, Laos and other countries.

We have an excellent sales team, and we can provide the best service and technical support while selling.Our goal is to ensure the development of the enterprise through high-quality services and high-quality products.We hope to establish business relations with the majority of companies in good faith and achieve mutually beneficial business goals through credit and cooperation.

Our competitive advantage

1.Competitive prices.Make the product competitive in your market.

2.Quick response: We promise to respond quickly as soon as we receive your request.

3.Excellent customer service: The company provides after-sales service to ensure customer satisfaction. We believe that long-term partnerships will bring loyalty.

4.We have our own research team, and the production process can be carried out strictly.

5.We have developed a stable customer base overseas and maintained long-term cooperation.

Faq

1.Who are we?

Our headquarters is located in Henan, China. It started in 1999 and is sold to Japan, South Korea, Vietnam, Laos and other countries.

2.How do we guarantee quality?

The company strictly controls product quality and strictly inspects products before shipment.

3.What can you buy from us?

Refining slag, calcium aluminate, calcium aluminate powder, pre-melted refining slag, sintered refining slag

4.Why do you want to buy from us instead of from other suppliers?

Founded in 1999, it cooperates with Wuhan University of Science and Technology, Luoyang Institute of Refractory Materials and other scientific research institutions, with an annual production capacity of 50,000 tons.

5.Refining slag packaging:

1) The net weight per unit is 25 kg (plastic woven bag); 1 metric ton of P.P bag (waterproof) with sling.

2) The net weight per unit is 25 kg (plastic woven bag); 1 metric ton of plastic film tray.

3) According to customer requirements.

6.Can you visit the site?

of course.Anytime.