Sintered refining slag

Brief introduction

Sintered refined slag is widely used in the steel smelting industry and can be used in production processes such as converters, electric furnaces, intermediate furnaces, and continuous casting. Sintered refining slag is a commonly used steelmaking auxiliary material in the metallurgical industry. It can improve the quality of steel by adding it to the molten steel during the steelmaking process, playing a role in impurity removal and tempering.

Classification

According to its main components and uses, sintered refining slag can be divided into various types such as oxidizing refining slag, alkaline refining slag, calcium magnesium refining slag, etc. Among them, oxidizing refining slag is mainly used to remove impurities such as oxides and sulfides in molten steel; Alkaline refining slag is mainly used to regulate the alkalinity of molten steel and improve the oxidation resistance of steel; Calcium magnesium refining slag is mainly used to reduce the sulfur content in molten steel, improve the toughness and strength of steel.

The main function of sintered refining slag is to remove impurities such as oxides and sulfides from the molten steel; Adjusting the chemical composition, temperature, and viscosity of molten steel; Reduce the gas content in molten steel, such as oxygen, nitrogen, etc.

Characteristic

1. Reasonable chemical composition is beneficial for quickly slagging and shortening smelting time.

2. Due to its fast slag formation, it can reduce the power consumption of refining time.

3. Reduce the consumption of refractory materials in steel ladles and increase their service life.

4. Has good desulfurization and deoxygenation effects.

5. Due to its low melting point, it has a good adsorption effect on impurities during argon blowing in the ladle and the tapping process of the electric furnace.

6. The ingredients are stable and uniform, and can be produced and packaged according to user needs.

Technical indicators

| Ai2O3 | SiO2 | CaO | MgO | Fe2O3 | TiO2 | S | P | N | F |

|---|---|---|---|---|---|---|---|---|---|

| ≥65 | ≤5.0 | ≥20 | ≤3.0 | ≤1.2 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.1 | / |

| ≥55 | ≤5.0 | ≥25 | ≤4 | ≤1.2 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.1 | 1.0 |

| ≥52 | ≤3.0 | ≥33 | ≤2.5 | ≤1.2 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.1 | 1.0 |

| ≥38 | ≤4.0 | ≥45 | ≤2.0 | ≤1.2 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.1 | / |

| ≥38 | ≤5.5 | ≥45 | ≤2.0 | ≤1.0 | ≤0.2 | 0.08 | 0.03 | 0.05 | / |

| ≥45 | ≤5.0 | ≥35 | ≥11 | ≤1.5 | ≤0.2 | ≤0.1 | 0.03 | / | / |

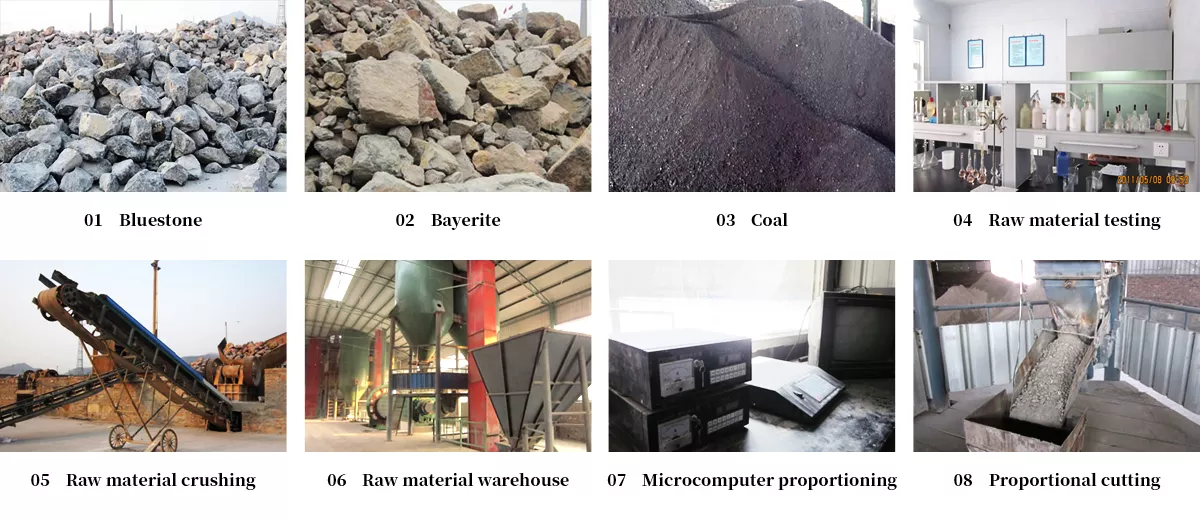

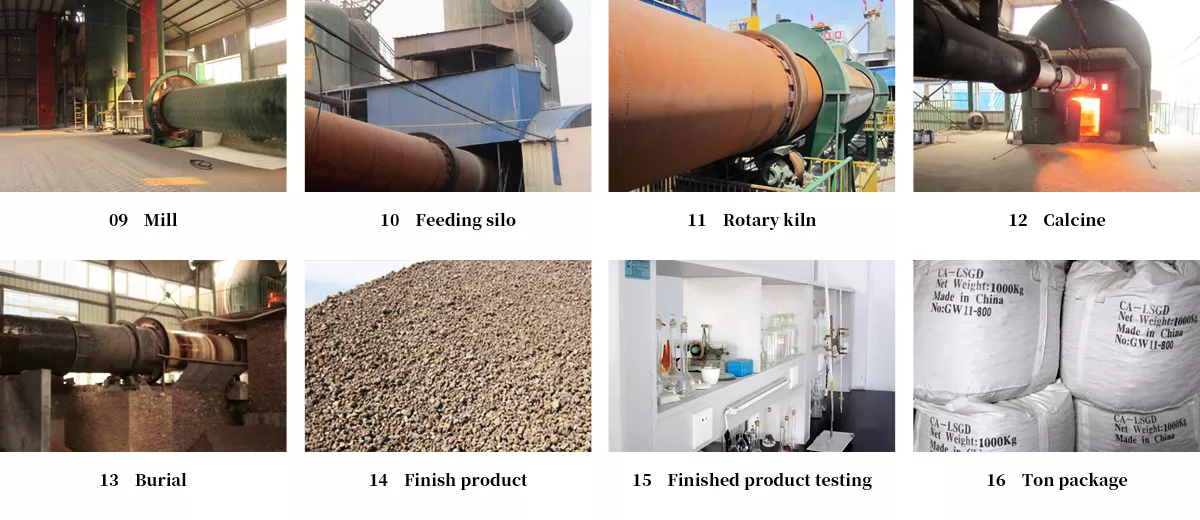

Production site

Process flow

Company profile

Gongyi Weida Co., Ltd. was founded in 1999, mainly produces refined slag, calcium aluminate, calcium aluminate powder, pre-melted refined slag, sintered refined slag and other products.The annual production capacity reaches 50,000 tons, and the products are sold well to Japan, South Korea, Vietnam, Laos and other countries.

We have an excellent sales team, and we can provide the best service and technical support while selling.Our goal is to ensure the development of the enterprise through high-quality services and high-quality products.We hope to establish business relations with the majority of companies in good faith and achieve mutually beneficial business goals through credit and cooperation.

Our competitive advantage

1.Competitive prices.Make the product competitive in your market.

2.Quick response: We promise to respond quickly as soon as we receive your request.

3.Excellent customer service: The company provides after-sales service to ensure customer satisfaction. We believe that long-term partnerships will bring loyalty.

4.We have our own research team, and the production process can be carried out strictly.

5.We have developed a stable customer base overseas and maintained long-term cooperation.

Faq

1.Who are we?

Our headquarters is located in Henan, China. It started in 1999 and is sold to Japan, South Korea, Vietnam, Laos and other countries.

2.How do we guarantee quality?

The company strictly controls product quality and strictly inspects products before shipment.

3.What can you buy from us?

Refining slag, calcium aluminate, calcium aluminate powder, pre-melted refining slag, sintered refining slag

4.Why do you want to buy from us instead of from other suppliers?

Founded in 1999, it cooperates with Wuhan University of Science and Technology, Luoyang Institute of Refractory Materials and other scientific research institutions, with an annual production capacity of 50,000 tons.

5.Refining slag packaging:

1) The net weight per unit is 25 kg (plastic woven bag); 1 metric ton of P.P bag (waterproof) with sling.

2) The net weight per unit is 25 kg (plastic woven bag); 1 metric ton of plastic film tray.

3) According to customer requirements.

6.Can you visit the site?

of course.Anytime.