Pre melted refining slag

Brief introduction

The pre melted refining slag has good fluidity and optimizes the kinetic conditions of desulfurization reaction, which can achieve deep desulfurization. Pre melted refining slag is made by sintering and melting limestone (containing CaO), magnesite (containing MgO), dolomite (containing CaO · MgO), tourmaline (containing BaO), and fluorite (containing CaF2) in a cupola. At present, pre melted refined slag can be produced through electric furnaces, pilot firing kilns, rotary kilns, horseshoe kilns, and cupolas for iron smelting. Different production methods and processes have an important impact on the quality of pre melted slag.

Characteristic

1. Pre melted refined slag: This product uses reassuring calcite and bauxite as the main materials, and is produced using gas open furnace melting process. CaO and A12O3 in the slag exist in the form of composite calcium aluminate;

2. This product simplifies the slag making process, has no flames, no dust, and is environmentally friendly;

3. The screened products are in block and granular form, with uniform and consistent composition, fast melting rate, and good flow and spreading properties;

4. Fast slag formation can reduce dust pollution in steel plants, shorten smelting time, improve production efficiency, reduce oxygen addition during smelting, and lower electricity consumption during refining;

5. High alkalinity, high sulfur capacity, significant desulfurization effect, with a desulfurization rate of over 85%;

6. It has adsorption effect on aluminum and silicon oxides in steel, which is beneficial for reducing non-metallic inclusions in steel and improving steel quality;

7. Less or no fluorite can be added to reduce the erosion of the furnace lining and ladle, reduce the consumption of refractory materials in the ladle, and improve the ladle life;

8. The curve function of product stability over time almost forms a straight line, avoiding many unsuitable phenomena caused by the wave and sawtooth curve functions of middle and low-end products in metallurgical production;

9. Synthetic slag has strong reducibility and strong deoxygenation ability. With the coordination of (Fe Si Mn), it can effectively remove oxygen from steel, and this slag can also effectively adsorb solid deoxygenation products and float together;

10. Not absorbent, not powdery, not spoiled, easy to store and transport.

Technical parameter

| Model | CaO(%) | Al2O3(%) | SiO2(%) | Fe2O3(%) | MgO(%) | P/S(%) | CaF2(%) | H2O(%) |

| DCA-1 | >45-50 | 38-42 | <6 | <1.5 | 3-5 | <0.05 | 2-4 | <0.5 |

| DCA-2 | >50 | 36-40 | <4 | <1.5 | <1 | <0.05 | <0.5 | |

| DCA-3 | 63-75 | 15-23 | <5 | <1.5 | 2-6 | <0.05 | 2-4 | <0.5 |

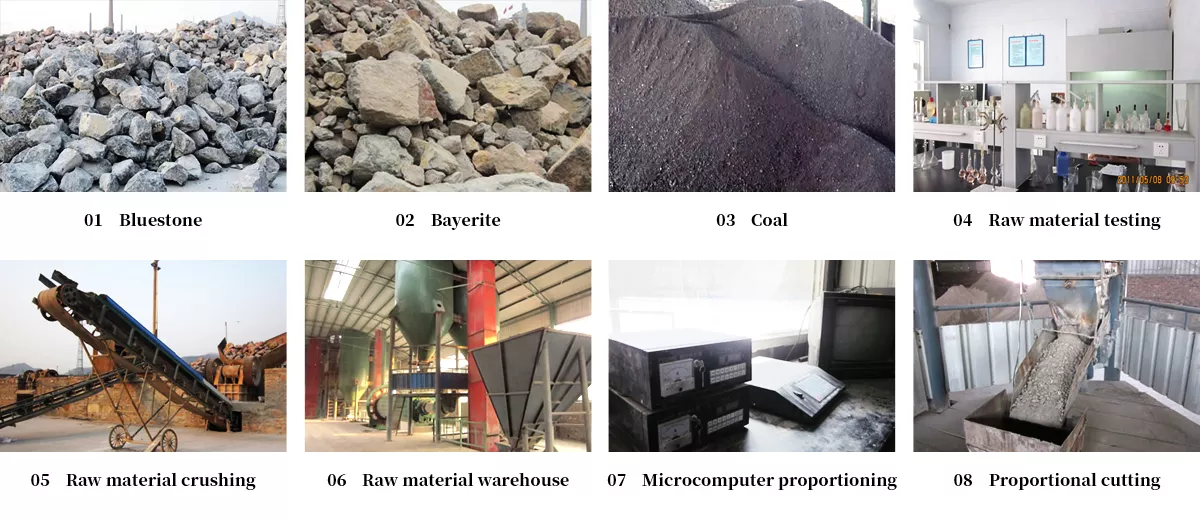

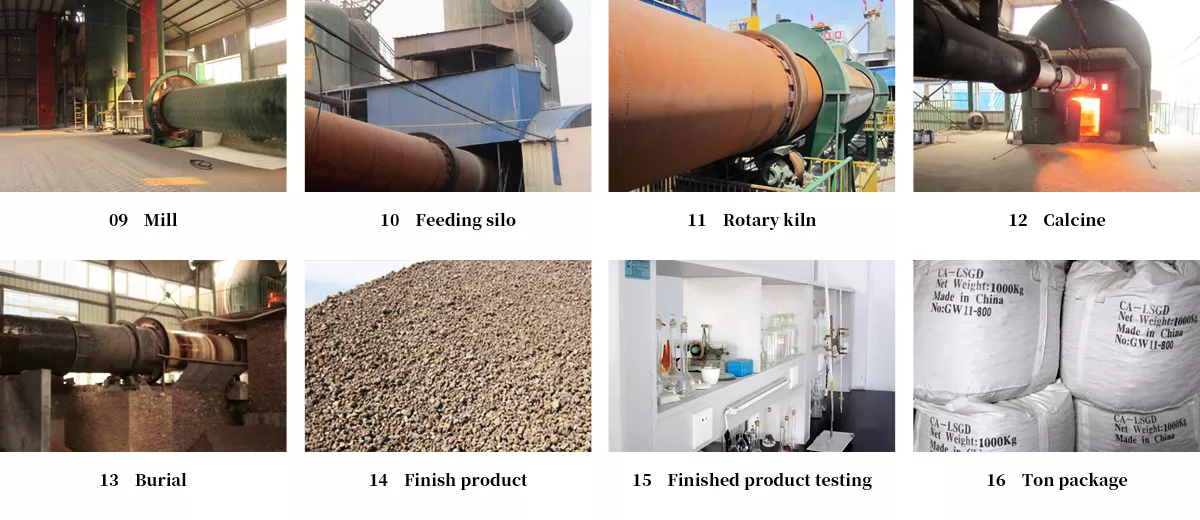

Production site

Process flow

Company profile

Gongyi Weida Co., Ltd. was founded in 1999, mainly produces refined slag, calcium aluminate, calcium aluminate powder, pre-melted refined slag, sintered refined slag and other products.The annual production capacity reaches 50,000 tons, and the products are sold well to Japan, South Korea, Vietnam, Laos and other countries.

We have an excellent sales team, and we can provide the best service and technical support while selling.Our goal is to ensure the development of the enterprise through high-quality services and high-quality products.We hope to establish business relations with the majority of companies in good faith and achieve mutually beneficial business goals through credit and cooperation.

Our competitive advantage

1.Competitive prices.Make the product competitive in your market.

2.Quick response: We promise to respond quickly as soon as we receive your request.

3.Excellent customer service: The company provides after-sales service to ensure customer satisfaction. We believe that long-term partnerships will bring loyalty.

4.We have our own research team, and the production process can be carried out strictly.

5.We have developed a stable customer base overseas and maintained long-term cooperation.