Refining slag

Introduce

Refining slag refers to the technology of mixing raw materials in a certain proportion and particle size, heating them below the melting point of the raw materials, sintering them together, and then crushing them into particle sizes for use. The main components of refining slag are CaO-CaF2 based, CaO-Al2O3 based, and CaO-Al2O3-SiO2 based. The main forms of refining slag include sintered refining slag, pre melted refining slag, and mixed refining slag. Refined slag is a necessary additive for deoxidation and desulfurization in the refining process of steel enterprises. It is an indispensable auxiliary material. Composite refining slag balls, formulated through high-tech technology, are more suitable for the purification of high-grade steel.

Application

The main components of refining slag are calcium aluminate, aluminum oxide, silicon oxide, calcium fluoride, magnesium oxide, etc. These metal ions combine to form a composite material of calcium oxide calcium fluoride base, calcium oxide aluminum oxide base, and calcium oxide aluminum oxide silicon oxide base, which is called refining slag. Refined slag is a necessary additive for deoxidation and desulfurization in the refining process of steel enterprises. Refined slag can be used as a flux and desulfurizer in steel smelting, which can reduce the viscosity of slag and improve steelmaking efficiency. Refined slag can also be used for soil improvement and agricultural production, which can improve soil fertility and crop yield.

Characteristic

The refined slag produced by Weida Company has advantages such as uniform chemical composition, low melting point, fast melting speed, reduced refining power consumption, and shortened refining time. It is increasingly valued by steel enterprises and is currently one of the important steelmaking additives.

Refining slag has greatly improved the efficiency of steel production, as well as the quality and performance of finished steel products, by replacing the production process that relied on high alkali materials, slag steel mixing, and external desulfurization in current steelmaking enterprises.

Technical indicators

| Ai2O3 | SiO2 | CaO | MgO | Fe2O3 | TiO2 | S | P | N | F |

|---|---|---|---|---|---|---|---|---|---|

| ≥65 | ≤5.0 | ≥20 | ≤3.0 | ≤1.2 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.1 | / |

| ≥55 | ≤5.0 | ≥25 | ≤4 | ≤1.2 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.1 | 1.0 |

| ≥52 | ≤3.0 | ≥33 | ≤2.5 | ≤1.2 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.1 | 1.0 |

| ≥38 | ≤4.0 | ≥45 | ≤2.0 | ≤1.2 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.1 | / |

| ≥38 | ≤5.5 | ≥45 | ≤2.0 | ≤1.0 | ≤0.2 | 0.08 | 0.03 | 0.05 | / |

| ≥45 | ≤5.0 | ≥35 | ≥11 | ≤1.5 | ≤0.2 | ≤0.1 | 0.03 | / | / |

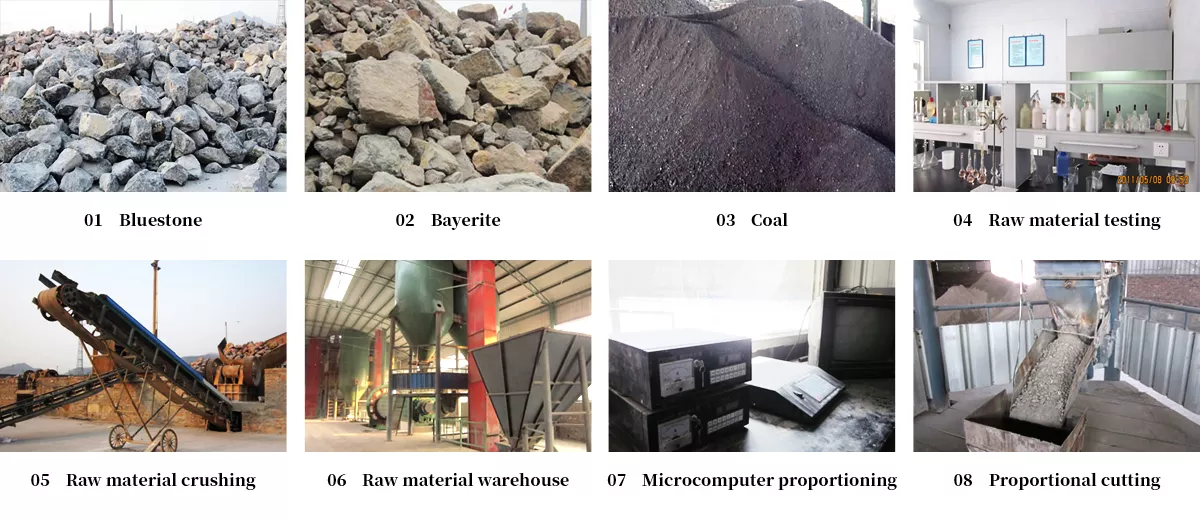

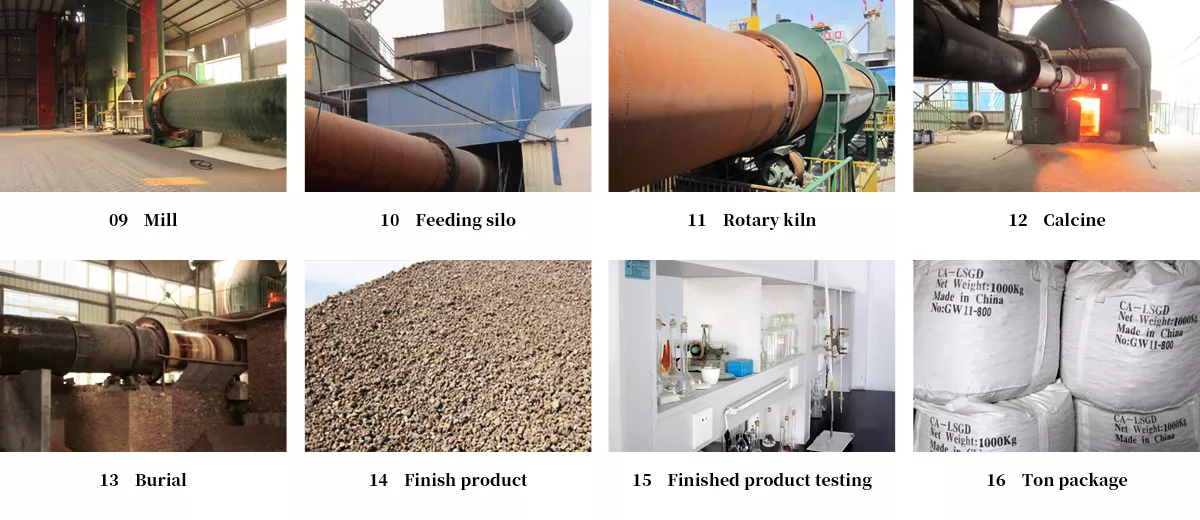

Production site

Process flow

Company profile

Gongyi Weida Co., Ltd. was founded in 1999, mainly produces refined slag, calcium aluminate, calcium aluminate powder, pre-melted refined slag, sintered refined slag and other products.The annual production capacity reaches 50,000 tons, and the products are sold well to Japan, South Korea, Vietnam, Laos and other countries.

We have an excellent sales team, and we can provide the best service and technical support while selling.Our goal is to ensure the development of the enterprise through high-quality services and high-quality products.We hope to establish business relations with the majority of companies in good faith and achieve mutually beneficial business goals through credit and cooperation.

Our competitive advantage

1.Competitive prices.Make the product competitive in your market.

2.Quick response: We promise to respond quickly as soon as we receive your request.

3.Excellent customer service: The company provides after-sales service to ensure customer satisfaction. We believe that long-term partnerships will bring loyalty.

4.We have our own research team, and the production process can be carried out strictly.

5.We have developed a stable customer base overseas and maintained long-term cooperation.